Koman combines stable materials with mature production lines and strict quality control to deliver exceptional quality products.

Only by combining mature technology with the best materials,could be created outstanding quality.

Every raw material used in our slab is carefully selected by our material experts to ensure its green and high quality.

Koman quartz stone ingredient:

All raw material have to through strict quality inspection, only the qulified quartz sand, resin and other additvie can be sent into the production line.

Mix the polymer resin with good quality quartz sand.

Manually fill the mold evenly with polymer resin and quartz sand.

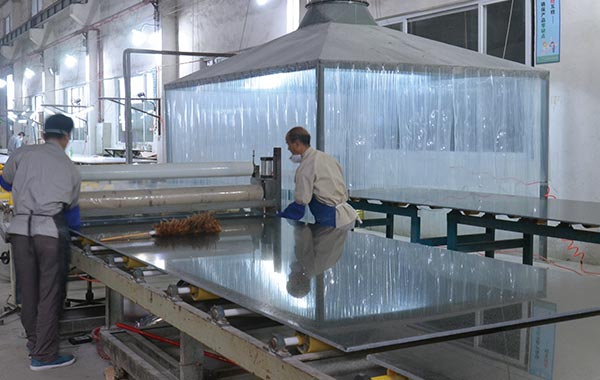

The moulds filled with the materials are sent to a vacuum machine with a pressure of 30,000 tons.

Send into the oven to curing by heating, and then send to the cooling machine.

Take off the mould after cooling, leave for 24 hours then start polishing.

The slabs are sent into the continuous polishing line, firstly scrape both side to flat, and then polish the surface.

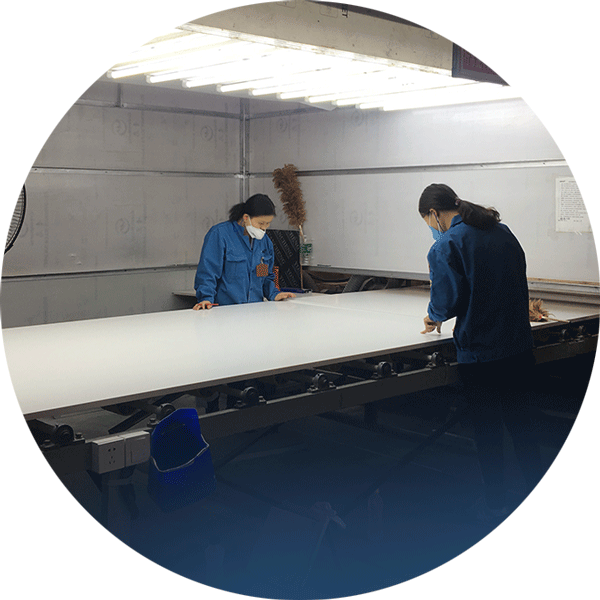

Our quality control line has three professional inspectors. Ensure that no quality problems are missed.

Obviously we are not satisfied with just one round of quality inspection of our products. In order to make each batch of our products are perfect and unified. Further checks and adjustments will be made in this step.

After cumbersome production and quality inspection, we will put a protective film on each slab before pack in the pallet ( branded protective film is available).

With 20 years export experience, make sure the slabs arrive your warehouse safety.

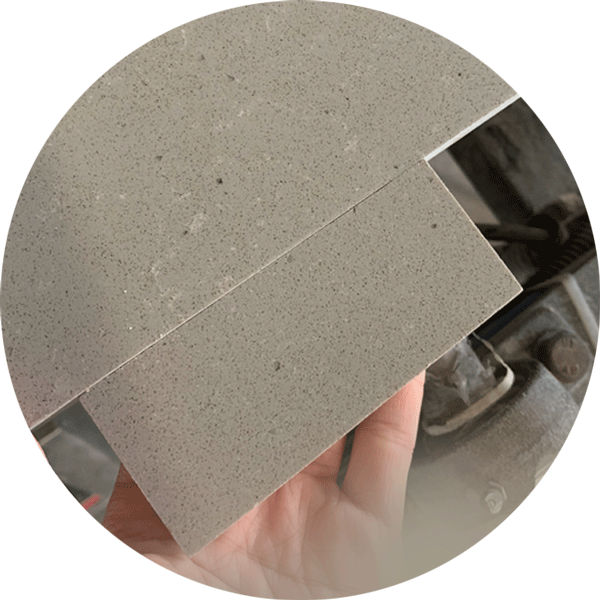

The thickness of each product will be accurately measured to ensure that the thickness of all products meet the standard.

The uniformity of color is very important for the product, we will carefully check and compare the color of each batch

The quality of the surface directly determines the customer’s first impression, so must ensure that the surface and back without air holes, no contamination.

Available customized color. Available customized size.

If you have any question, please don’t hesitate to let me know.

Monday-Friday 09:00-18:00

Talk about your needs

*Your email information is absolutely secure and will not be disclosed to third parties for any reason.

Could you please keep our color catalog?

*Your email information is absolutely secure and will not be disclosed to third parties for any reason.